Classifiers

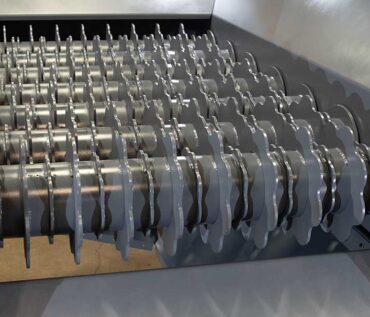

The Barclay Classifier, configured in 2-inch, 4-inch sizes, and 6- inch sizes perfectly complements our Primary and Secondary Shredders. Barclay Classifiers feature a 50-square-foot screening area and is driven by a 4hp 3-phase motor which means you can process 16 tons of material per hour economically. Our Daisy Wheel Disc Screen Classifier features heavy-duty shafts and abrasion-resistant discs, which maximize uptime and minimize maintenance.

Why Choose Us

Obtaining your required chip size in the fewest amount of cuts is key when operating a profitable tire recycling operation. Barclay Classifiers improve operational efficiency by ensuring only the rubber that requires further size reduction is reprocessed.

Research & Development

Specifications of a tire shredder classifier can vary depending on the specific application and the type of tires being processed.

- SEW Eurodrive Gearmotors provide years of worry free operation.

- Process approximately 16 tons of material per hour.

- Compact footprint for easy integration into existing systems.

- Capacity: 16 tons/ per hour of classified material.

- Screening Area: Large 50-square-foot screening area handles a wide variety of tires.

- Bearings: Spherical roller.

- Shafts: 7 x 2 15/16-inch Diameters.

- Electrical: 480V/60HZ, 390V/50HZ 3-Phase.

- Leg Mounts: Removable legs.

- Gearbox/Motor: 5hp integrated inverter gearmotor.

- Style: Disc screen with abrasion-resistant discs.

- Feed: Reversible accepts chute.

- Chip Size: Produces various configurations of nominal chips: 6-inch, 4-inch, and 2-inch sizes

- High-Quality Material: Heavy-duty shafts and abrasion-resistant discs help minimize regular maintenance.

- Accuracy: High-level sorting accuracy ensures the shredder is processing tires of a consistent size and type.

- Durability: High-quality materials are designed to withstand the wear and tear of continuous use.

- Maintenance: Easy to maintain and service.