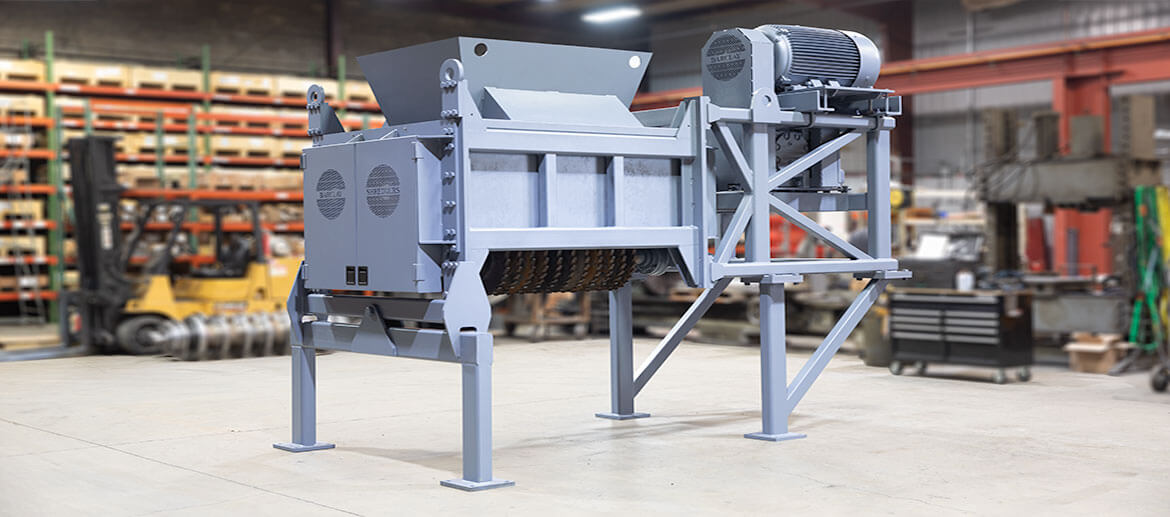

Barclay Secondary Tire Shredders

Secondary Tire Shredders take feed stock from the primary shredder and process chip into smaller pieces for a variety of end markets. Barclay Secondary Shredders can be configured to meet the demands of your specific end market requirements.

Why Choose Us

The Barclay 2.0S Secondary Tire Shredder is a top-feed shredder designed to further reduce the size of tire material previously processed. With cascading blade sizes ranging from 2.00 inches thick to 1.60 inches, this machine is perfect for producing chips for TDF or granulating and is ideal for running in-line behind a primary shredder.

Why Barclay?

Barclay Secondary Shredders features a modular knife/base combination utilizing only three bolts to connect the knife to the base.

- Easier knife changes

- Minimizes the amount of maintenance required

- Reduces the overall maintenance time

Barclay 2S Secondary Tire Shredder Specifications

Weight: 33,000 lbs

Gearmotor: SEW Eurodrive 200hp, 3-Phase, 360-480V, 50-60Hz

Shaft Specifications:

– Diameter: 13.5 inches

– Orientation: Through Feed

– Rotation Speed: 20-28 RPM

Controls: Fully wired to accept line connection. Soft start motor starter.

Safety: Emergency stop buttons mounted on front and rear of shredder.

Cutting Chamber: 48 inches wide, 23 cuts at varied spacing from 1.60 to 2.00 inch

Cutting Knives:

– Cru-Wear tool steel

– 1.60 to 2.00 inch thick heat treated and precision ground

– Reversible with two cutting edges per knife

– Modular step-down sizes allows knives to be sharpened up to six times.

Knife Bases: Replaceable heat treated and precision ground alloy steel

Drive Train Protection: Couplers with shear pins protect from overloading

Rotating Strippers: Strippers rotate continuously to clear debris from the cutting chamber.

Throughput: 12-15 tons per hour of graded 2-inch tire chips

Input Material: Pre-cut tire shreds